-40%

4utoHydria 160 Gal 30 HP Rotary Screw Air Compressor Dual Voltage All-in-One

$ 5268.91

- Description

- Size Guide

Description

4utoHydria 30HP 230V/460V/60HZ/3PH

Rotary Screw Air Compressor With Tank & Dryer

Power : 30HP / 22KW,

Voltage : 230V/460V /60Hz / 3 Phase,

Capacity: 125 cfm,

Tank: 160 Gal. ASME

Output Pipe Diameter : NPT 1”,

Max Working Pressure : 125 psi / 8 bar ,

Motor RPM : 3600/Minimal transmission losses

Item Weight : 2182 lbs

Package Dimensions : 87 x 82 x 54 inches

How to determine how much horsepower you need

The horsepower is related to the ability of the screw air compressor to fill its tank with air. You should have a motor with enough horsepower to fill the compressor's tank so you do not run out and have lengthy downtimes while the tank fills back up with air. How much air gets used is determined by the cubic feet per minute (CFM) and the pounds per square inch (PSI) of air the equipment and tools you are using require. You want to measure the total amount of CFM and PSI your tools and equipment need and choose a compressor with enough horsepower to produce both.

Application:

Air Brushing,Blow Cleaning,Bolting/Wrenching,Brad Nailing/Stapling,Cutting,Drilling,Finish Nailing,Framing Nailing,Grinding,

HVLP Painting,Hobby Nailing,Hobby Painting,Inflation,Roof Nailing,Sanding,Spraying,Surface Prep

A rotary air compressor is designed to be used in industrial and commercial applications.

They are made to supply a continuous amount of air to items like jackhammers, pneumatic pumps, and sandblasters.

Garage & Industrial & Light Duty

Features a programmable control system

Reduces your air system footprint and allows for easy maintenance

Caution:

Please read the operate manual carefully before start the compressor working

— Don’t dismantle any connector or equipment when machine is

running. Otherwise, the high-pressure gas and high temperature will

hurt you seriously.

— Please pay more attention to parts such as pump, oil tank and

pipelines, because they are high temperature when machine is running.

— Don’t try to change the working pressure rated . Because change

working pressure exceeding the rated range will cause machines to

overload and stop to work.

——

— Provide proper grounding connection for electric parts according

to electric security regulations. Use suitable wires matching the

working power, otherwise they will burnt out due to high temperature

or some other dangerous events occur.

— The compressed air for breathe use is prohibit.

Regular maintenance interval schedule,please check manual in the package:

Every 50 hours or weekly

--- Check oil level.

--- Check intake filter, if necessary clean it.

--- Drain condensation water from oil tank.

Every 500 hours

--- Check and adjust belt tension if necessary (belt driven only)

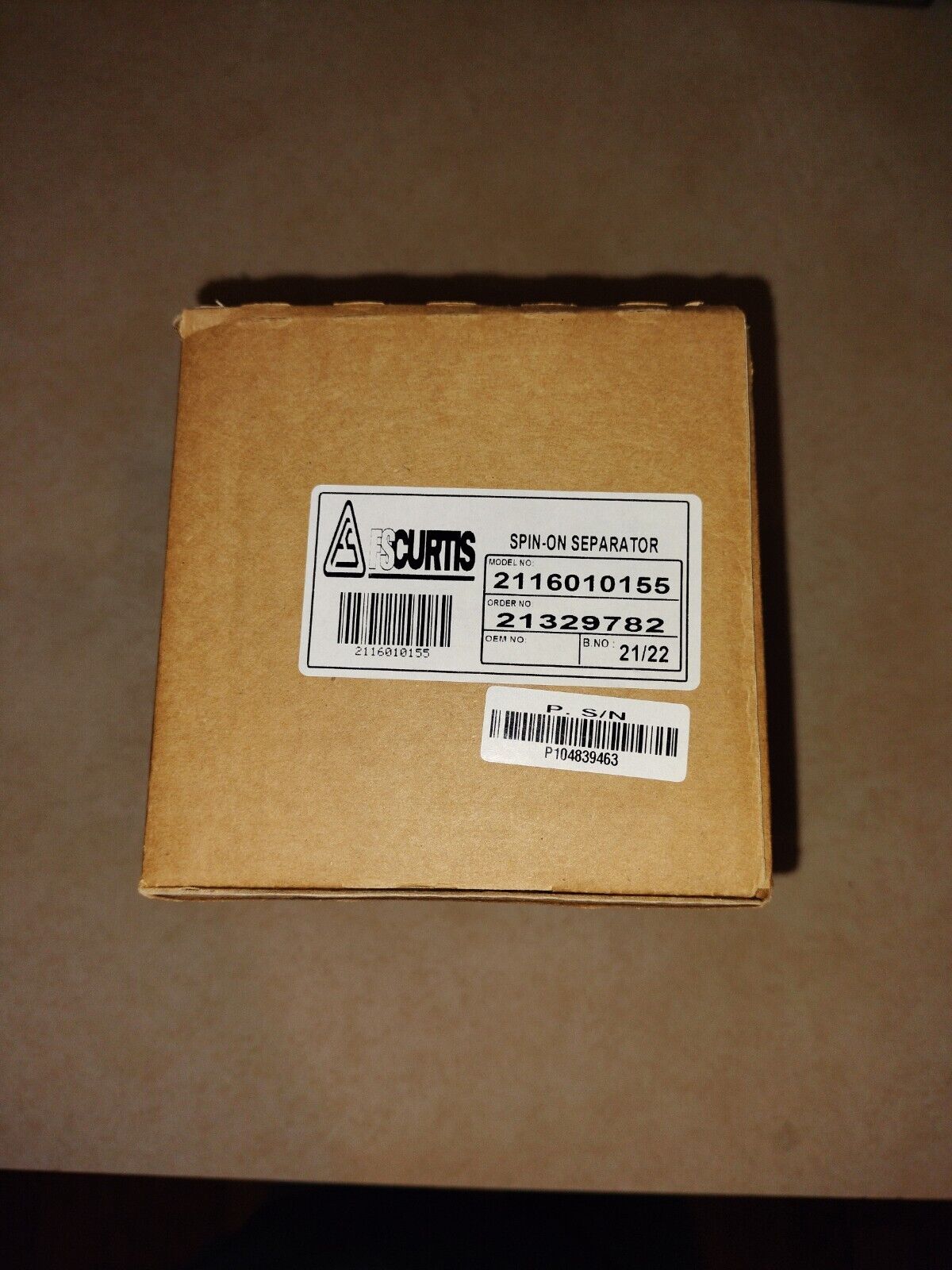

Every 2000 hours

--- Replace lubricants (for mineral lubricants oil)

--- Replace oil filter.

--- Replace intake filter

Every 4000 hours

--- Replace lubricants (for synthetic lubricants oil)

--- Replace oil separator

--- Clean cooler for dirt

Attention:

1、Replace filter element and lubricant after first 500 hours of operation.

2、Use incorrect lubricant oil and spare parts will cause compressor damage, only use original

manufacture oil and parts.

3、The service life of compressor depends on the environment conditions such as dust, vent

etc.

Guarantee period:

4utoHydria products enjoy 1-year guarantee calculated from the buying date for complete machine.

we will not offer free of charge service to repair damaged machine due to installation error, using

error, bad oil, maintenance error and use of not original manufacturer